History

In 2019, the Nobel Prize in Chemistry has

been awarded to John B. Goodenough, M. Stanley Whittingham, and Akira

Yoshino for their research in improving battery technology. It is the invention

of the lithium-ion battery (LIB).

M.Stanley Whittingham discovered the concept of intercalation electrodes in the 1970s and created the first rechargeable lithium-ion battery, which was based on a titanium disulfide cathode and a lithium-aluminum anode, although it suffered from safety issues and was never commercialized. John Goodenough expanded on this work in 1980 by using lithium cobalt oxide as a cathode. The first prototype of the modern Li-ion battery, which uses a carbonaceous anode rather than lithium metal, was developed by Akira Yoshino in 1985 and was commercialized by a Sony and Asahi Kasei team led by Yoshio Nishi in 1991. For more information: The

Nobel Prize in Chemistry 2019

To understand the lithium-ion battery we need to understand Lithium itself.

Lithium

Lithium is an alkali metal with atomic number 3 (2,1) and a mass of 6.941g/mol. (The mole value is equal to the number of atoms in exactly 12 grams of pure carbon-12 (12 g C = 1 mol C atoms = 6.022 × 1023 C atoms). So lithium has 3 protons, 3 electrons, and 4 neutrons being an alkali metal it is soft, highly reactive, flammable, and forms oxides.

Fig: Atomic Structure of a Lithium

It has a single valance electron in its outermost orbit which is easily removed to form bonds and other compounds. That very property is used to make a Li-ion battery.

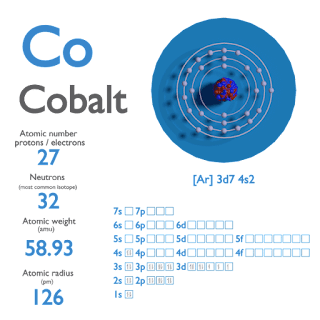

But we need something to which Lithium can give its outermost electron. For these purposes, Cobalt, Manganese, Iron Phosphate, LiNiCoAlCo2, LiNiMnCoO2, and LiMn2O4 are the most know materials and oxides used in Li-ion cells.

In this case study, we will be using Cobalt as an example.

Cobalt

Lithium cobalt oxide (LiCoO2) is widely used in lithium-ion battery cathodes.

Breaking Down a Lithium-Cobalt Battery

Lithium-Cobalt batteries have three key components:

The cathode is an electrode that carries a positive charge and is made of lithium metal oxide combinations of cobalt, nickel, manganese, iron, and aluminum.

The anode is an electrode that carries a negative charge, usually graphite.

The electrolyte is a lithium salt in liquid or gel form and allows the ions to flow from the cathode to the anode (and vice versa).

How it Works

When the battery is charged, lithium ions flow via the electrolyte from the cathode to the anode, where they are stored for usage. Simultaneously, electrons pass through an external circuit and are collected in the anode through a negative current collector.

When the battery is generating an electric current (i.e. discharging), the ions flow via the electrolyte from the anode to the cathode, and the electrons reverse direction along the external circuit, powering up the EV.

The composition of the cathode largely determines battery performance. For EV batteries, this is where the lithium-cobalt combination plays a crucial role.

Figure: Flow of electrons and Li ions during charge and discharge

Design

Fig: Common battery Design

In most batteries, the negative electrode of a conventional cell is made of graphite which is basically carbon and it has a limited maximum capacity of 372 mAh/g researchers are looking for other options. For the positive electrode different types of metal oxide can be used. There are different materials to choose from, and the most common one we have heard of is cobalt.

Electrolytes

Electrolyte alternatives have also played a significant role, for example, the lithium polymer battery. Polymer electrolytes are promising for minimizing the dendrite formation of lithium. Polymers are supposed to prevent short circuits and maintain conductivity. Solid polymer electrolytes (SPE) and Gel polymer electrolytes (GPE) are the most used electrolytes.

Advantages of solid-state electrolytes

- No electrolyte leakage

- No organics to degrade

- Improved safety – non-flammable

- Could enable Li metal and high voltage cathodes (values)

- Enhanced thermal stability

- Could be fabricated in air

- High Li+ transference numbers values vs:

- > 0.25 – liquid electrolyte these values are for liquids > 0.5 – polymer electrolyte

Let's see the chemical breakdown.

The positive electrode (cathode) half-reaction in the lithium-doped cobalt oxide substrate is:

The negative electrode (anode) half-reaction for the graphite is:

The full reaction (left to right: discharging, right to left: charging) being:

The overall reaction has its limits. Over-discharging supersaturates lithium cobalt oxide, leading to the production of lithium oxide, possibly by the following irreversible reaction:

Overcharging up to 5.2 volts leads to the synthesis of cobalt (IV) oxide, as evidenced by x-ray diffraction:

At anode: xLi+ + xe- + 6C ↔ LixC6

At cathode: LiCoO2 ↔ Li1-xCoO2 + xLi+ + xe-

Compared to Ni-Cd batteries:

No memory effect

Higher voltages (~3 ×)

Self-discharge <5 % per month

Negative Electrode

Fig: Types of negative Electrodes that can be used in Li-ion

Positive Electrode

Fig: Types of Positive Electrodes that can be used and their characteristics

Alongside these electrodes, research has been going on. Companies like Tesla are already using Lithium Iron Phosphate batteries in their Model 3 cars which seems to be cheap in comparison to others with only 0.14 kWh (High

Voltage Battery Information). Whereas electric cars with NMC batteries include, as of 2020: Audi e-tron GE, BAIC EU5 R550, BMW i3, BYD Yuan EV535, Chevrolet Bolt, Hyundai Kona Electric, Jaguar I-Pace, Jiangling Motors JMC E200L, NIO ES6, Nissan Leaf S Plus, Renault ZOE, Roewe Ei5, VW e-Golf, VW ID.3 and EV6.

Note: If you want to learn more about batteries and technology I would recommend the following material which has gone into great detail.

Battery

Reference Book

Handbook

of Batteries

Figure: Future Expectation

Future

.png)

.png)

Comments

Post a Comment